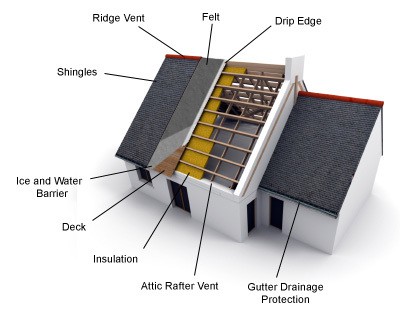

2 underlayment this synthetic layer which replaces felt paper covers the entire roof deck and is the second line of defense against leaks after the shingles.

Roof order rafters shething drip edge shingles.

In a w pattern along each length.

Once the apron s in place fasten it with sheet metal screws.

What is a drip edge you ask.

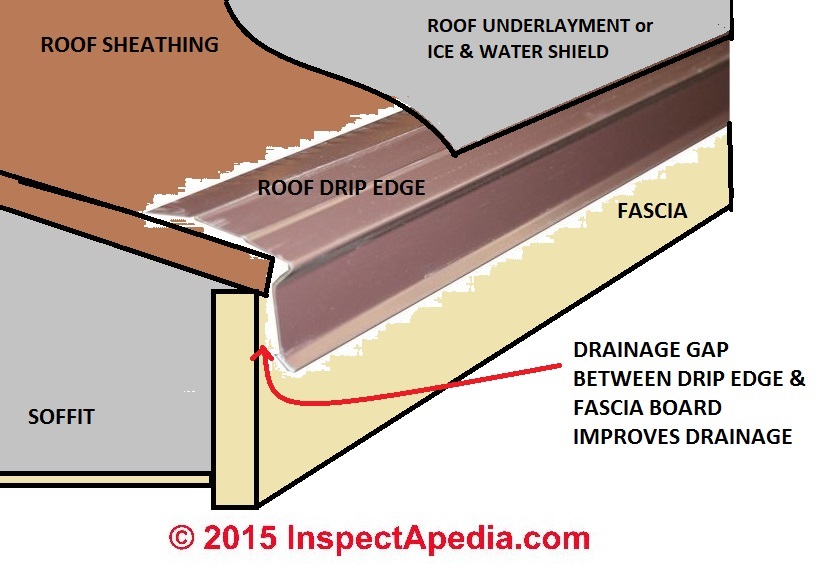

Without a drip edge water may end up beneath the shingles and may cause damage to various parts of the home.

Its purpose is to give water an edge to drip safely off your roof onto the ground or into the gutter.

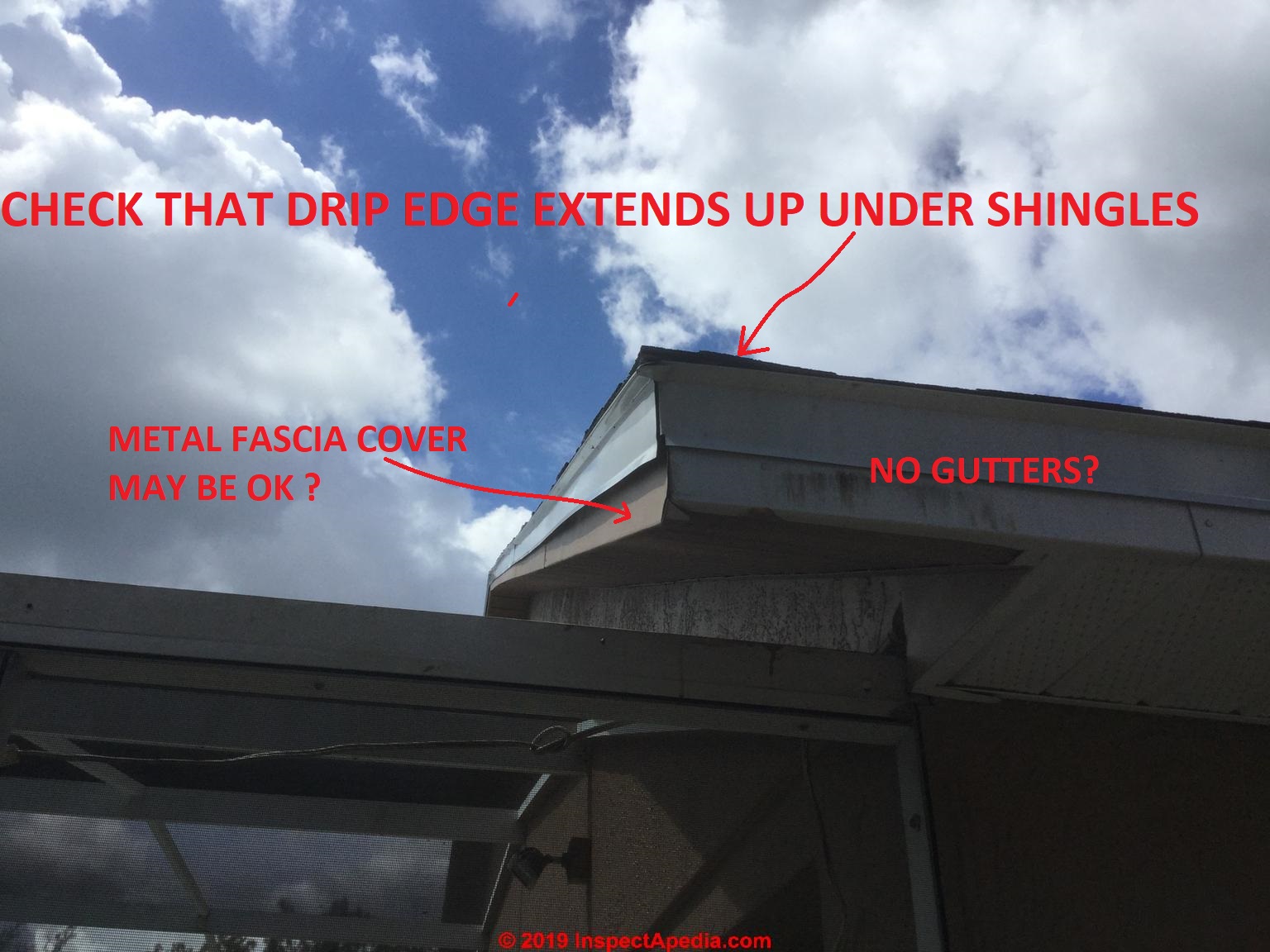

Drip edges shall extend not less than 1 4 inch 6 4 mm below the roof sheathing and extend up back onto the roof deck not less than 2 inches 51 mm.

To shed water away from the eave most roofers add a metal drip edge right to the roof deck covering it with the membrane.

A drip edge shall be provided at eaves and rake edges of shingle roofs.

Also called drip edge flashing or d metal they serve a vital function by directing water away from the fascia and into the gutter.

If there s a drip edge installed where the fascia meets your shingles and the gutter is hung below the drip edge get some roll flashing and tuck it up under the drip edge and over the top of the gutter.

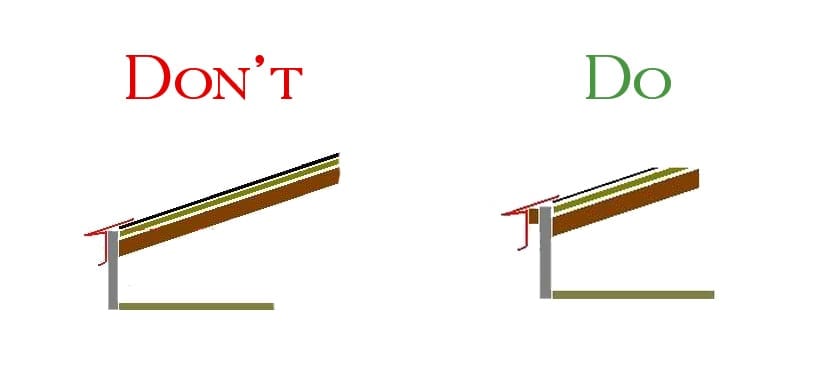

In order for the roof edge seal or a band of roof cement to be effective at holding shingles down they must be bonded directly to wide metal drip edge.

Zip system panels install fast and stay flat for a roof that looks as good as it performs.

Adjacent segments of the drip edge shall be lapped a minimum of 2 inches 51 mm.

In addition to helping to hold the shingles from blowing off sealing the shingles down can help block wind driven rain from getting between the drip edge and the shingle and making its way onto the underlayment.

Drip edge metal valley flashing dormer chimney and kickout flashing are types of roof flashing that shed water away from the connections between roofs walls chimneys and other building assemblies.

For any asphalt shingle roof a drip edge is required by most local building codes.

Gibraltar building products 2 in.

Adjacent segments of drip edge shall be overlapped not less than 2 inches 51 mm.

Then i nail it down at about 4 in.

The drip edge shall extend back on the.

The vertical leg of drip edges shall be a minimum of 1 1 2 inches 38 mm in width and shall extend a minimum of 1 4 inch 6 4 mm below sheathing.

Drip edges are metal sheets usually shaped like an l installed at the edge of the roof.

Zip system sheathing and tape provides a water resistant durable underlayment for many finished roof coverings including metal tile and asphalt shingles fiberglass shingles and cedar shingles.

I usually use drip edge with a minimum 5 in wide roof leg.

It is a small piece of l shaped metal with a little kick out on the edge that goes around the perimeter of your roof.